Marine electrical expert Nigel Calder explains why boat batteries emit hydrogen and how to minimise the dangers

During the final stages of charging, all lead-acid batteries break down some of the electrolyte in a battery into hydrogen and oxygen. With sealed batteries, such as gel cells and AGMs, the gases are normally contained within the battery, although in certain circumstances (notably, persistent overcharging), enough internal pressure can build up to open pressure release valves and vent the gasses. With wet cell batteries – the type that need topping up from time to time – the gases are always vented.

Hydrogen, which is highly explosive, is much lighter than air, so typically will rapidly rise and disperse, so long as there is even minimal venting from the top of a battery box and from the top of the compartment in which the battery box is housed. However, if a pocket of gas forms, any spark (such as from a brushed electric motor kicking on) may set off the hydrogen, on occasion resulting in a powerful explosion. This is what blew the top off the Fukushima nuclear power plants in Japan. Occasionally, internal short circuits create a spark inside batteries that can set off a hydrogen explosion within the battery, blowing the case open. Note that this can occur with sealed batteries as well as with wet cell batteries.

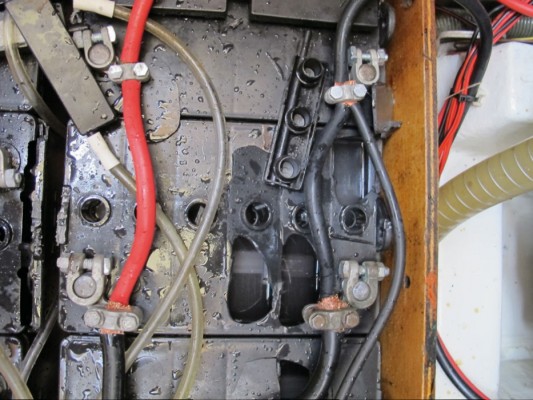

There is far more electrical kit on modern cruising boats than there was in the past. Batteries are worked harder than ever before, with a greater likelihood of hydrogen emissions, especially when powerful charging devices are in use, with charging voltages pushed to the limits that batteries can tolerate. Most cheap automotive chargers (such as the one in use on Thursday’s Child at the time of the explosion) have poor voltage regulation, increasing the risk of overcharging and substantial hydrogen generation. But even with expensive, tightly-controlled chargers, batteries are sometimes deliberately pushed to a vigorous ‘gassing’ stage, notably when ‘equalising’ or ‘conditioning’ wet-cell batteries.

When batteries are worked hard, they generate a fair amount of internal heat. This increases a battery’s ability to absorb charging current without its voltage rising, which effectively disables any voltage regulator on the charging device, resulting in gross overcharging. The battery can get into a condition known as ‘thermal runaway’ in which it soaks up all the charging current that can be thrown at it, converting this into hydrogen, oxygen and heat – a dangerously potent mix. The only effective way to guard against this is to have temperature sensing at the battery, linked to the charging device. However, temperature sensors don’t work when they are stuck to the top of a battery, which is where I normally see them, as there is an insulating pocket of air inside the battery. Sensors need to be fastened directly to the battery posts, or else taped to the side of a battery about half way down. They are an essential piece of the charging system for any batteries that will be worked hard. Automotive chargers typically do not have a temperature sensor.

Even with vigorous hydrogen formation, so long as a battery compartment is vented from the top, allowing the hydrogen to escape, hydrogen will almost always be safely vented from the boat. But if a pocket builds up and there is any kind of a spark, either inside or outside the battery, the consequences can be devastating.

Nigel Calder is YM’s technical guru and author of the esteemed Boatowner’s Mechanical and Electrical Manual (Adlard Coles).