Promotional feature in association with GJW Direct. A well maintained impeller pump should prevent a failed impeller, says Bruce Jacobs of Rubicon 3

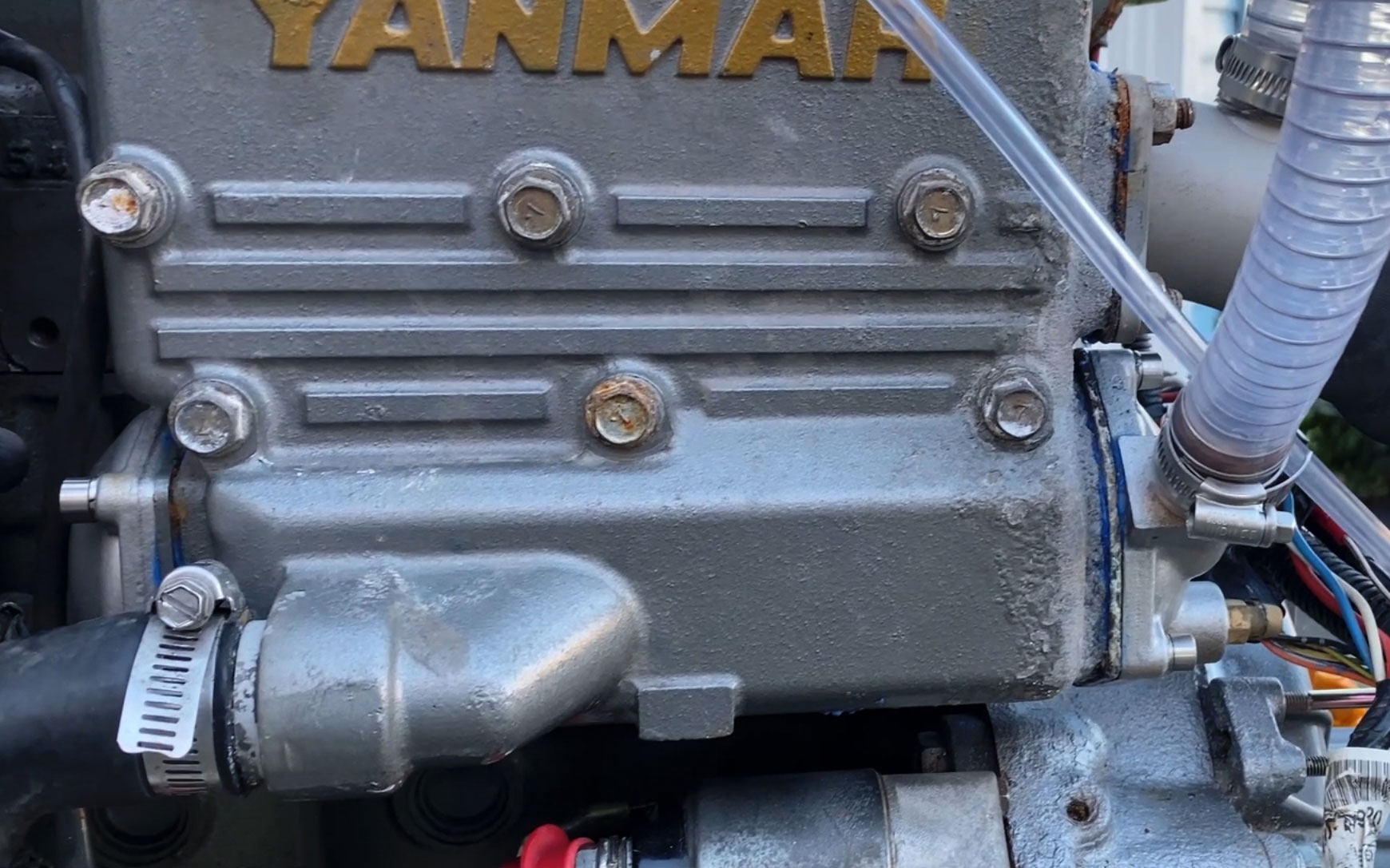

How to: change a marine diesel water impeller

One of the key checks when you start up your engine is that your raw water cooling system is working properly. You should see water coming out of the exhaust.

The water and exhaust gasses will have travelled from the engine through a reinforced rubbed hose via various water traps and loops to the skin fitting.

You need to see a good flow of water, though amounts vary from engine to engine.

If you don’t see exhaust water, you need to locate the raw water impeller by following the hose from the raw water strainer. Some impellers are belt-driven, while others are gear-driven straight from the engine, but the principle is the same.

REMOVAL

Faceplate

Close your raw water seacock then undo the faceplate screws taking care not to lose them in the bilge.

Put a tray or tea towel down before you start, and ensure you use the right tool so you don’t damage them.

As the faceplate comes off, a small amount of water will drain out – have a sponge ready.

Impeller

To take the impeller out, best practice is to use an impeller puller, which lifts the impeller out from behind, avoiding damage to the housing.

In reality, many people use a pair of fine-nose pliers – not ideal, but fine as long as you’re careful to pull straight.

Give it a good inspection, looking for cracks and wear.

Missing bits

Inspect the rubber impeller for damage or wear on the blades.

If any bits are missing it is imperative to check these aren’t stuck in the cooling system as they can prevent proper cooling.

Trace the water system and undo the hoses and heat exchanger to check for bits.

There is some fragile copper tubing in the heat exchanger so very gently push out any rubber you find with soft electrical wire.

Corrosion

Another problem you might encounter is wear or corrosion in the housing, face plate or lift plate – the cam that forces the splines to bend, creating the pump’s lift effect.

Held in place with grub screws, this can be replaced.

Check the rubber O-ring seal for the faceplate (some just have paper gaskets) and while you’re there, check the drive shaft seal at the back of the housing – a leak can seriously damage an engine.

FITTING

- New impellers usually come with some grease or lubricant. Put that around the fins and then slide it in, taking care to put it in the right way round – it has a front and a back – and that you bend the fins in the direction that the engine will turn – normally bent towards the engine side and away from the sea-

water inlet. Smear a little grease on the O-ring or gasket and replace the face plate.

- If it’s an emergency and you don’t have a spare gasket, you may be able to reuse the old one if it’s in good condition. Otherwise there are some sealants you can smear on the inside of the face plate, but only to get you home

- Good practice is to replace your impeller before it fails. If you do the proper checks when you start the engine – raw water seacock open, water strainer clear and water coming out of the exhaust, it shouldn’t fail. Look on the packet of the impeller to see what the recommended service hours are, and make sure you change it before it fails.

GJW Direct offers some of the most comprehensive and competitive boat insurance policies on the market. With more than 175 years in marine insurance, when you insure your yacht with us, you’re dealing with the boat insurance specialists, leaving you free to enjoy your time on the water. www.gjwdirect.com

With thanks to the experts at rubicon3adventure.com, the UK’s specialists in adventure sailing and training.