Some countries are threatening to ban the use of copper in antifouling by 2020 – but will other products take up the challenge? Duncan Kent reports

What happens when they ban antifoul?

As much as I dislike antifoul, we all need some form of hull protection to keep critters at bay. It’s been a couple of decades since lead-based TBT antifouling was outlawed for leisure craft and since then we’ve relied almost entirely on copper-based biocides to keep the weed and barnacles away. Now, some countries including Sweden, Denmark and The Netherlands are considering banning all use of copper in antifouling paints. So where does that leave us?

Why has this happened?

At one time, copper was used on all ships to prevent fouling. But then in the 1950s scientists discovered a cheaper material – tin – and started producing tri-butyl tin (TBT) paints that were rapidly accepted the world over. This continued until the 1980s, when it was discovered that TBT had a harmful effect, causing some shellfish to change gender. After more detailed research it was officially accepted that TBT was nasty stuff and it was banned – first for leisure craft, then for all sea-going vessels in 2003.

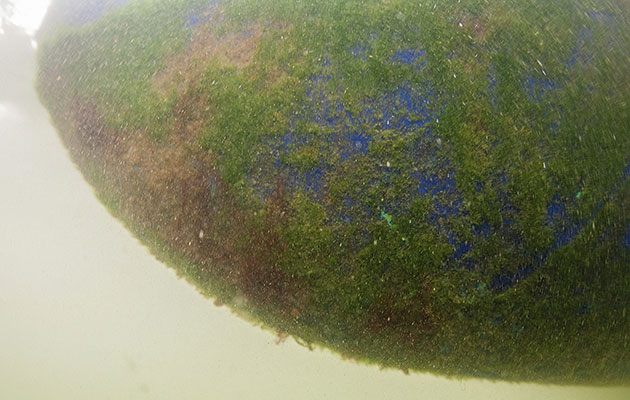

Copper is held in suspension and painted onto hulls

The coatings industry had no choice but to fall back on copper. Currently around 95 percent of antifoul coatings now contain copper or cuprous oxide (CuO) derivatives as the active biocide that repels weed and molluscs.

The copper reacts with oxygen in the air to repel molluscs and weed

This biocidal product is held in suspension in various types of medium, from soft ablating paints to hard epoxy resin, and reacts with oxygen in the air to produce cupric ions that are repulsive to living molluscs and most organic weed growth.

A fouled propeller is far less efficient and effective

The quantity of biocide in antifoul paint is not the only factor affecting its performance. The material that holds the paint together is equally important since it determines how quickly the biocides will be released. It must be carefully adjusted to suit the type of copper and any additional biocides used. While the quantity of copper and biocide may affect its working life, the ability of the resin paint to release them in the correct proportion and at the correct rate is equally, if not more important.

There’s often confusion over what coating does what and which you should use, so here’s a short guide to what is available (and legal) at the time of writing (Feb 16):

Hard antifoul paint

Sometimes referred to as ‘contact leaching’ antifouling paint, hard antifoul is a copper biocide product suspended in a solid coating, which leaches out slowly over time when in contact with seawater, but is durable enough to take a grounding without damaging the coating. It’s commonly used for racing yachts, especially if it’s the type that can be burnished smooth before a race, and for small cruisers that are kept on a drying or semi-drying mooring.

The problem with these coatings is that once the biocides have been exhausted, the remaining hard paint film remains intact. Although it can be overpainted with compatible antifouling, at some point you will need to clean off all the old, flaking layers of ‘dead’ paint – either by scraping or blasting.

Extreme types of hard antifoul include high-copper, resin-suspension products such as Coppercoat, which are said to last for up to 10 years with just the occasional rub down with fine sandpaper or a Scotchbrite pad.

Eroding antifoul paint

Antifouling is an annual DIY job for most boat owners

Also known as soft, ablative or self-polishing antifoul, this type of coating is much softer and, being soluble, is designed to erode fairly quickly so a fresh layer of biocide is always present on the surface.

A self-polishing copolymer (SPC) antifoul will release biocide at a nearly constant rate throughout its life. The diffusion of the biocide on the hull surface is primarily due to a chemical reaction between the paint and seawater, which means it remains effective even when the vessel is moored up, but its effectiveness is boosted when the boat moves through the water, cleaning and replenishing its surface. This does result in the active biocides being ‘consumed’ more quickly than in a hard antifouling, so you need to apply at least two coats (more if you’re in a high fouling area) if it’s to last the whole season.

Unlike hard antifoul (solid copper coatings excluded), boats painted with eroding antifoul can be hauled and relaunched without repainting, since the biocides are chemically bound to the paint and are only active in water.

Copper-based coatings ban

Most yacht owners use a soft, eroding copper-based antifouling paint

Some EU authorities have raised concerns over the copper compounds currently found in antifoul paints, leading to restrictions and partial bans in Sweden and The Netherlands.

According to a number of well-informed sources I have spoken to recently, including Albert Willemsen, a renowned environmental consultant, these bans or restrictions have come about through perceived risks to environmentally sensitive local environments and there has been no proven negative impact of copper-based antifoul on the marine environment.

An antifoul ban would reduce the fuel efficiency of shipping

Twofold problem

Fouling significantly reduces the fuel efficiency of shipping and increases emissions

Despite all the concerns about copper, two important mitigating factors are causing regulatory authorities to have a serious rethink before introducing an outright ban on the use of copper, post-2020. One is that fouling dramatically increases hull drag, which in turn leads to significantly heavier fuel consumption – at a time where governments all over the world are trying to reduce carbon emissions.

Originally from Russia and South China, the Chinese Mitten Crab is now common around the Rivers Thames and Medway

The other concern is that vessels with less effective antifouling will transport invasive marine species, both flora and fauna, beyond their normal habitat.

Native to the north-west Pacific, styela clava sea squirts can now be found around the UK

Apparently there are more than 70 varieties of non-native marine species already thriving in UK waters and, whilst some happily cohabit alongside our native species, others are smothering native species or depriving them of food.

Japanese Wireweed was discovered on the Isle of Wight in 1973 and has spread to Scotland

Alternative products

Various DIY solutions have been invented over the years to reduce or overcome the problems of using harmful, expensive chemicals. Some are pretty impractical: multiple, peel-off layers of PVC film, freshwater baths and even generous dollops of nappy rash cream. Few, if any, could be developed into a functional and effective system.

Enterprising manufacturers have come up with some rather more sensible and effective alternatives. None has solved the problem completely, but some interesting new products are on trial at the moment, which could well come to fruition within the next decade.

Among these are Teflon- and silicone-based ‘nanotech’ coatings, using technology already found in marine gelcoat polish. Cornwall-based Nanotech Marine is working on a self-cleaning nanotech antifoul and the first three-year test results look promising. It’s only intended for motorboats at the moment, but the company is looking into ways of applying the same principles for sailing boats.

Nanotech Marine’s antifoul is a silicone-based product, said to create a surface so slippery (at a molecular level) that no weed or mollusc can get a grip on the hull. Research has shown it does indeed work, but only on boats capable of high speed (10 knots or more), which are used regularly, as the coating relies on the boat’s motion through the water to wash off biofouling. They’re not so effective for a boat left on a mooring or in a marina for weeks on end, so even if you’ve got a fast yacht, a nanotech coating may have to be used in conjunction with another product, such as an ‘ultrasonic’ bio-deterrent system.

Silicone-based nanotech paints contain millions of tiny particles that can permeate a boatyard via clothing, cloths, spillage or even by taking to the air in the breeze. If anyone nearby is painting their topsides, tiny silicone molecules will adhere to the surface, leaving hundreds of tiny ‘fish eyes’ in the finish. For this reason, many yards that do professional paint jobs refuse to allow silicone products on their premises.

Ultrasonic antifoul systems can be a credible addition to antifoul paints but not a replacement

The issue with ‘ultrasonic’ deterrent systems is that they can’t keep an immersed hull totally free of weed and have been proven to offer limited protection against some types of fouling, so you still need to apply a biocidal coating to the hull.

No more DIY antifouling

DIY antifouling could soon be banned

Increased regulation is likely to hit our wallets hard, by restricting or banning DIY application of antifoul paints. The EU Health and Safety Executive (HSE) is looking at how we deal with the annual task of antifouling – how we handle the product, what personal protection we take in the event of spillage, where and how we dispose of old coatings, and so on.

If the HSE decides we can’t be trusted to take care of ourselves and our environment, we’ll be left with no choice but to have the job done professionally, which inevitably means at a vastly increased cost.

There has been mention of alternative, less hazardous coatings that could be created for the DIY market, but as anybody who has recently tried to find an effective weedkiller in a retail DIY shop will know, ‘less hazardous’ will undoubtedly be synonymous with ‘less effective’.

The way forward

So where do we go from here? The effective antifoul paints that we’ve become used to might start to disappear from chandlers’ shelves and we’ll be forced to spend more on professional products and application.

After discussing it in depth with a wide selection of well-informed professionals in the marine industry, together with paint manufacturers, the British Coatings Foundation, British Marine, The International Council of Marine Industry Associations, the RYA and members of the boating public, sadly I have come to one inevitable conclusion – that the cost of owning a boat will take another big hike in the coming few years, with the resultant loss of yet more boat owners on modest incomes who can only keep their boats by doing much of the maintenance themselves.

What is a biocide?

A biocide’s ability to repel weed and slime depends on its concentration in the coating – and also on how quickly it is released

Copper metal (Cu) and cuprous oxide (CuO) are the basis of most metallic biocides currently found in antifoul paint. Both these products are very effective in deterring larval, mollusc and weed growth, but their ability to repel weed and slime depends on their relative concentration in the paint.

While CuO is a very good antimicrobial product, it does require a high concentration to be fully effective against all types of marine fouling.

Paints that contain less base copper metal, or use less powerful ingredients such as Copper Thiocyanate, often contain extra biocides such as Zinc Pyrithione or organic algaecides such as Irgarol and Diuron, to cope with slime and weed growth. It is these organic boosters that are currently causing a stir, as some people think they could cause similar problems to TBT.

For this reason, the regulation process for algaecides and biocides in Europe has been made much more arduous and it now takes a lot more time, research and, consequently, expense to get one of these products licensed. This might be economically viable for commercial shipping, but not for the leisure craft market, so we will inevitably end up having to use an inferior (or very much more expensive) product should a total ban on unregulated biocides be introduced.

One of the latest biocides to be authorised is Selektope (generic name Medetomidine), made by the pharmaceutical giant Astra Zeneca. Instead of killing off marine growth, it is said to temporarily stimulate the octopamine receptor in the larvae of molluscs, causing them to be harmlessly repelled from the hull. The company’s research has apparently proved that it works at extremely low concentration levels (3g/litre) in any paint, and needs no other biocide for a barnacle-free hull. Sadly it’s not as effective on weed, so will also have to contain approved algaecides to be effective.